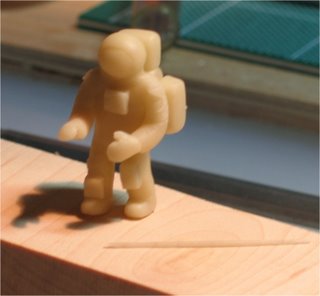

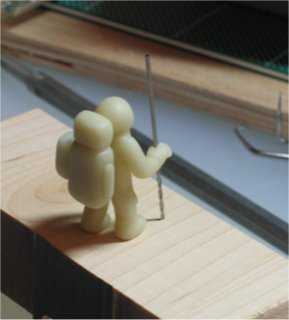

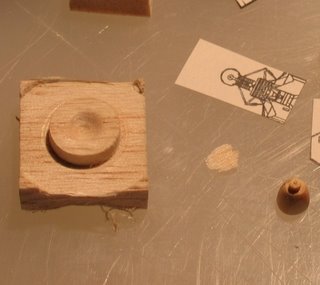

The figure was tested on top of the lunar surface before gluing both in place onto the wooden base. My wife did a great job with the stain and varnish for the circular base. The Gnomon tool was put in place. A small antennas was drill on the top of the life support pack, it is a cat whisker, don't get me wrong here, cats looses once in a wile some of their wiskers, you just have to be extra attentionate to find them on the floor before passing the vacuum cleaner, cat wishers have the property to be very flexible and straight at the same time, they greatly simulate the properties of antennas.

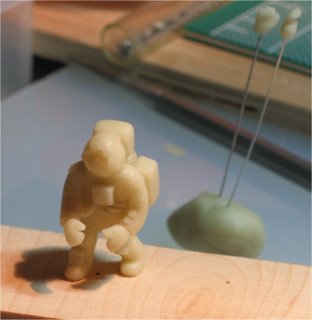

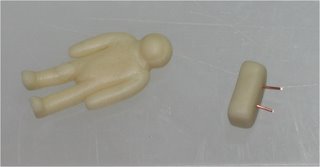

The figure was tested on top of the lunar surface before gluing both in place onto the wooden base. My wife did a great job with the stain and varnish for the circular base. The Gnomon tool was put in place. A small antennas was drill on the top of the life support pack, it is a cat whisker, don't get me wrong here, cats looses once in a wile some of their wiskers, you just have to be extra attentionate to find them on the floor before passing the vacuum cleaner, cat wishers have the property to be very flexible and straight at the same time, they greatly simulate the properties of antennas. Here we can see size comparison. The helmet front was painted in a way that we could see the reflexion of the moon surface with the sky, the sky being black and the moon surface being yellowish, because of the gold plate visor.

Here we can see size comparison. The helmet front was painted in a way that we could see the reflexion of the moon surface with the sky, the sky being black and the moon surface being yellowish, because of the gold plate visor. Here's some details works for the tools equipments, I think the pictures are speaking for themselves, you can also see the size of the home made decals.

Here's some details works for the tools equipments, I think the pictures are speaking for themselves, you can also see the size of the home made decals.Go to Step 7 or back to Step 5